All

Plastics

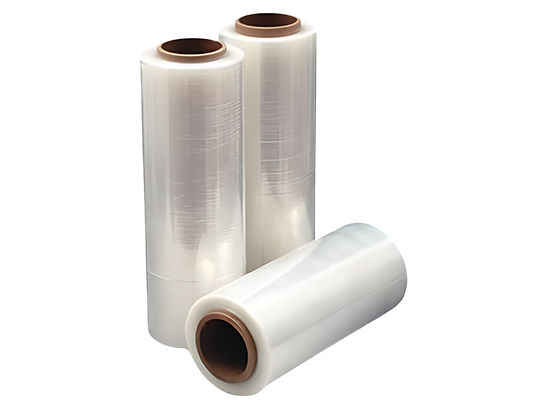

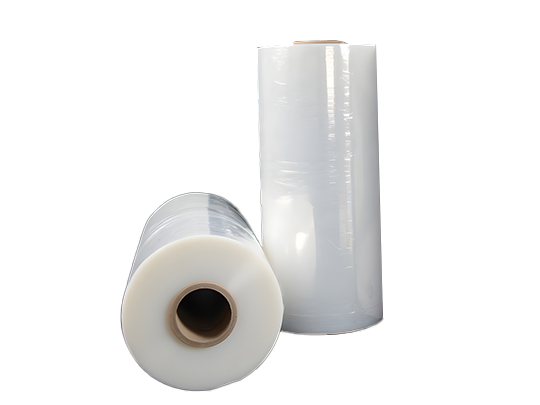

Stretch Film

Injection Molding Solution

Tapping Machines

Wrapping Machines

Uncategorized

Adhesive Tape

Machinery

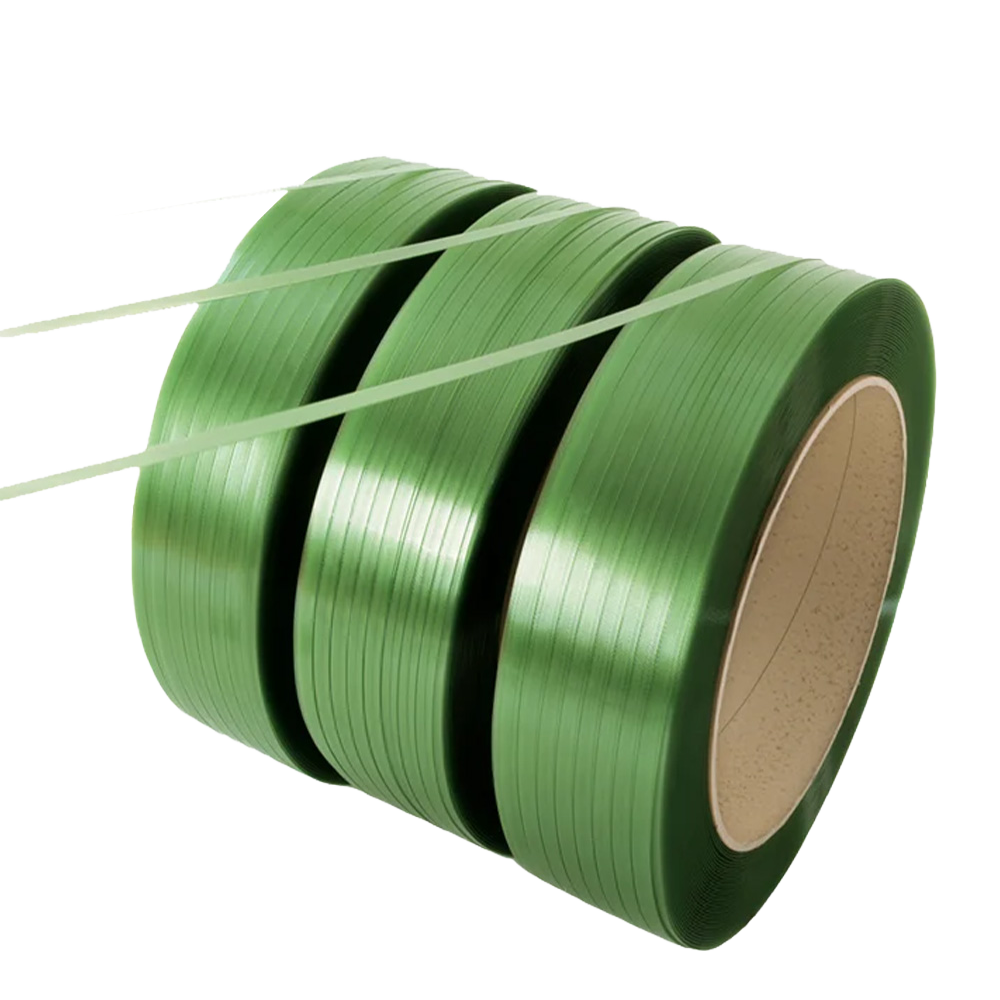

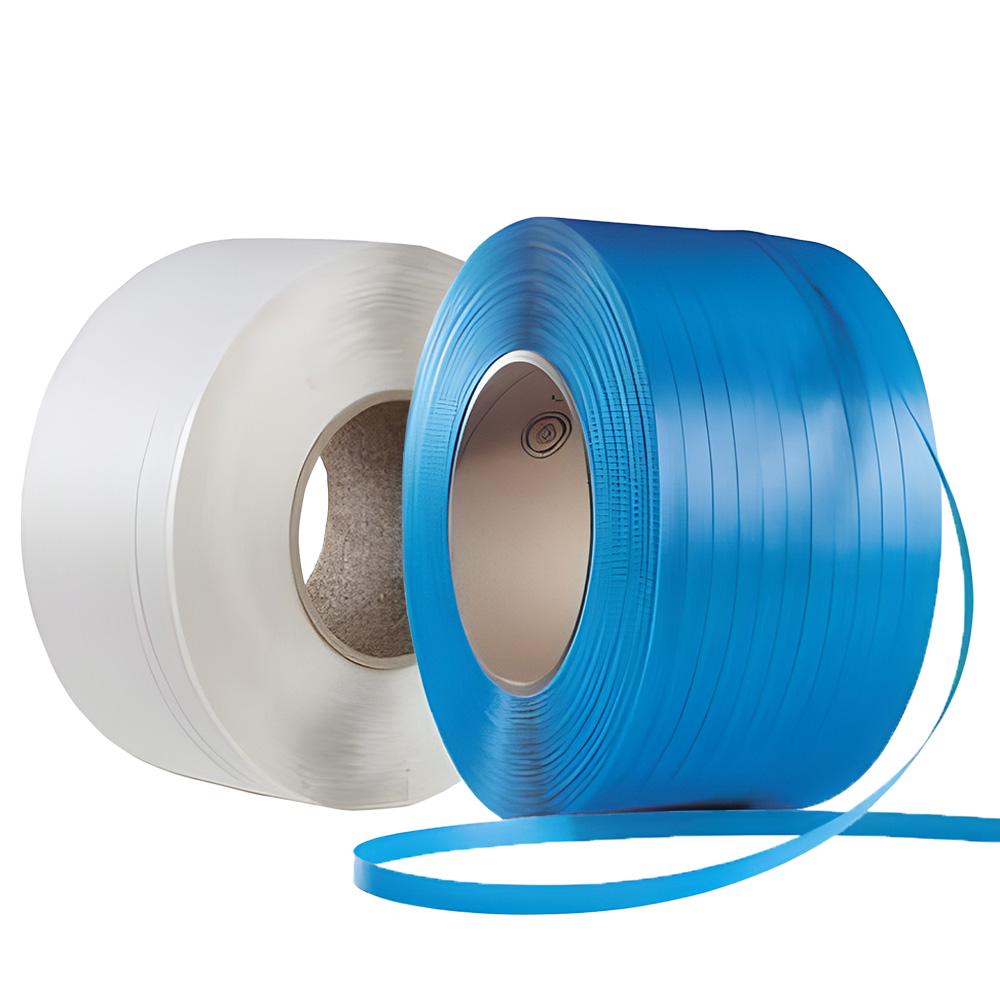

PET / P.P Strap

Shrinking Machines

Polyethylene Film

Materials

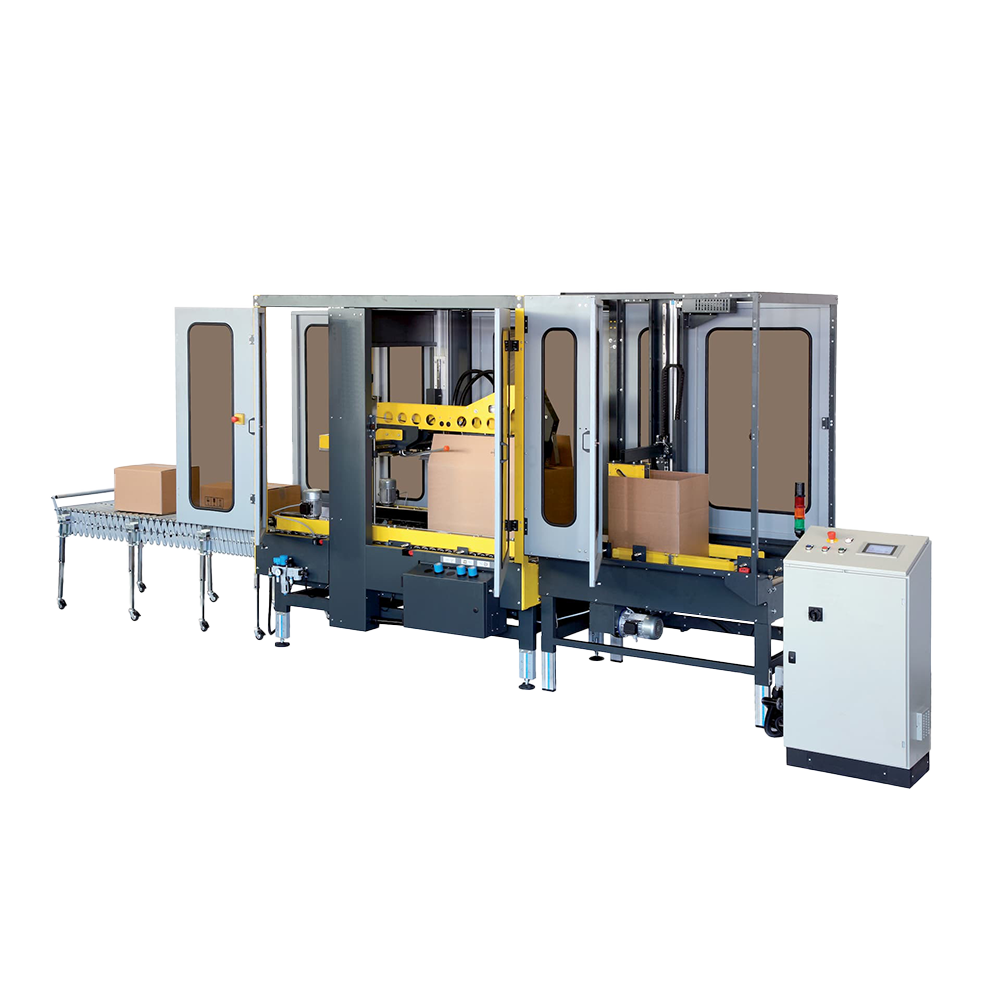

Case Erectors

Polyolefins

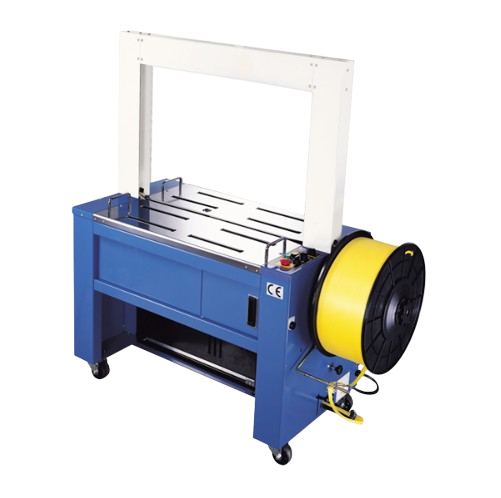

Strapping Machines

Agri Stretch Film

Strapping Tools

Net Pallet Wrap

Bundling Machines

Pallets

Boxes

Crates

Vacuum Machines

All

Plastics

Stretch Film

Injection Molding Solution

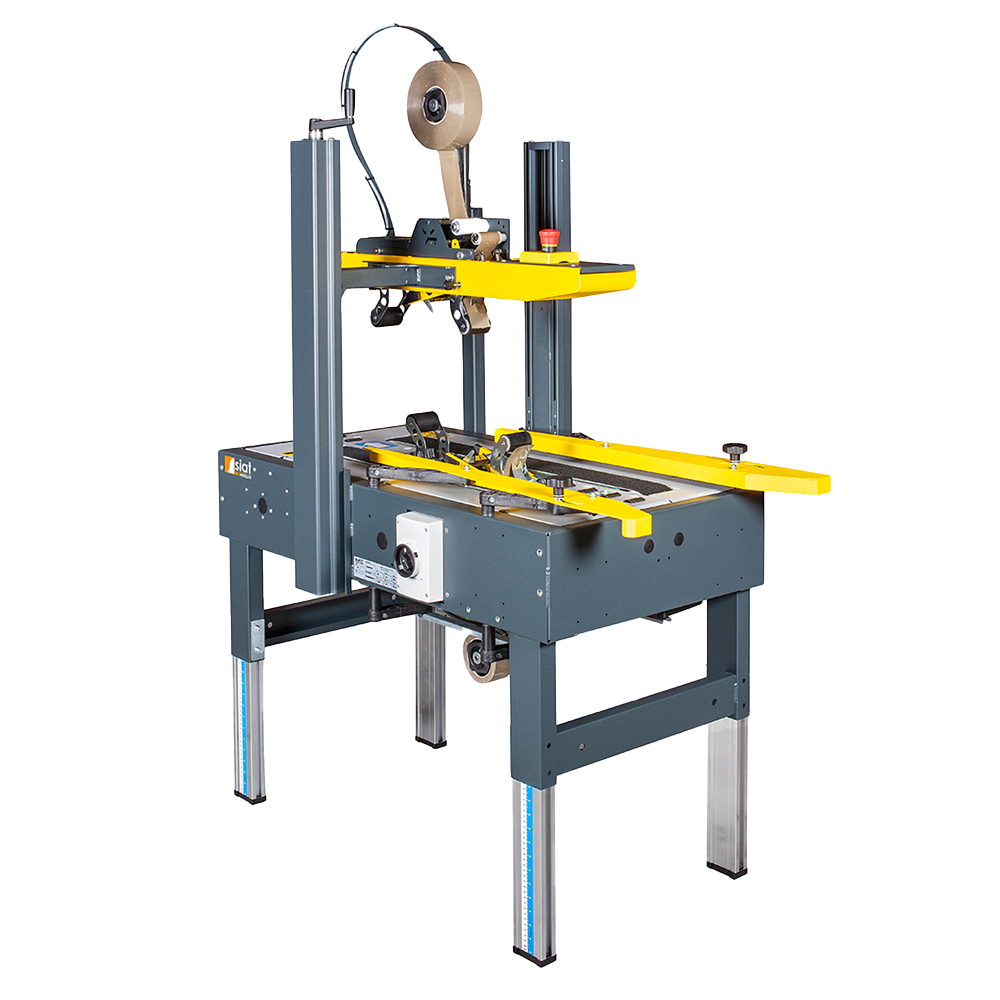

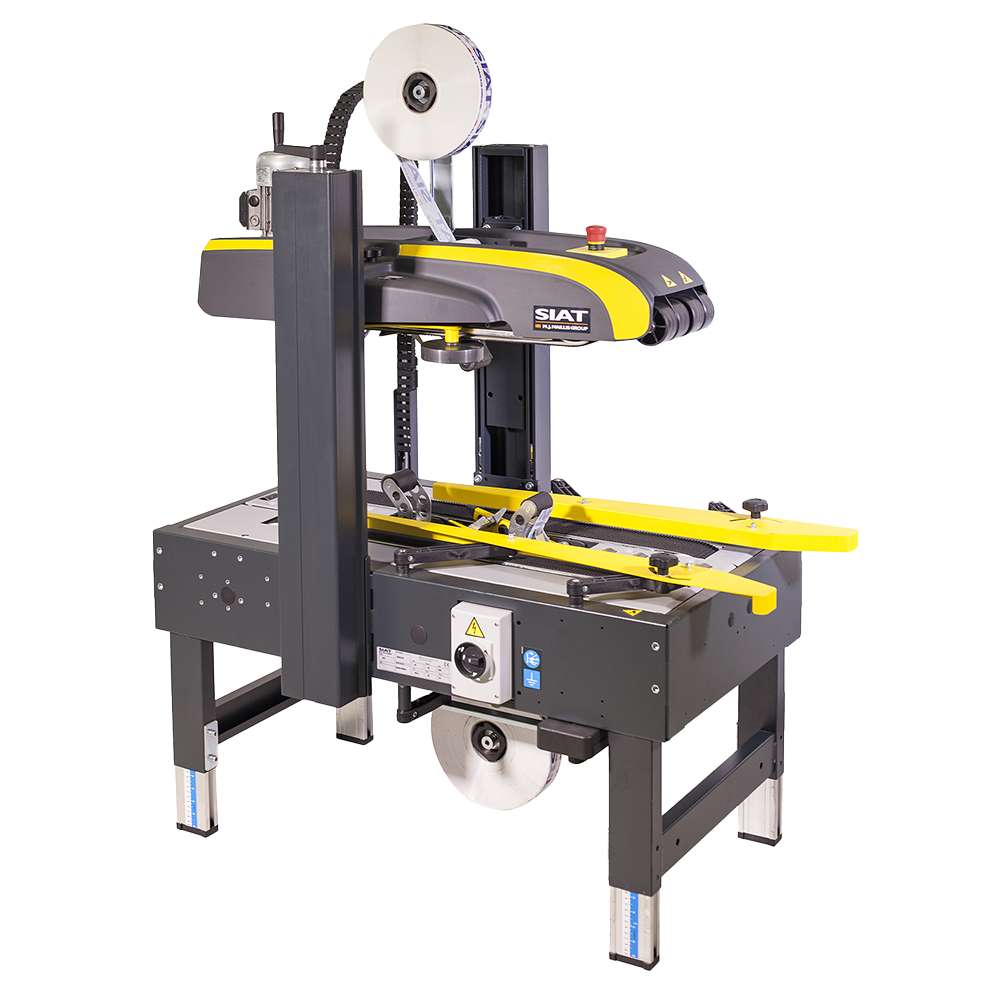

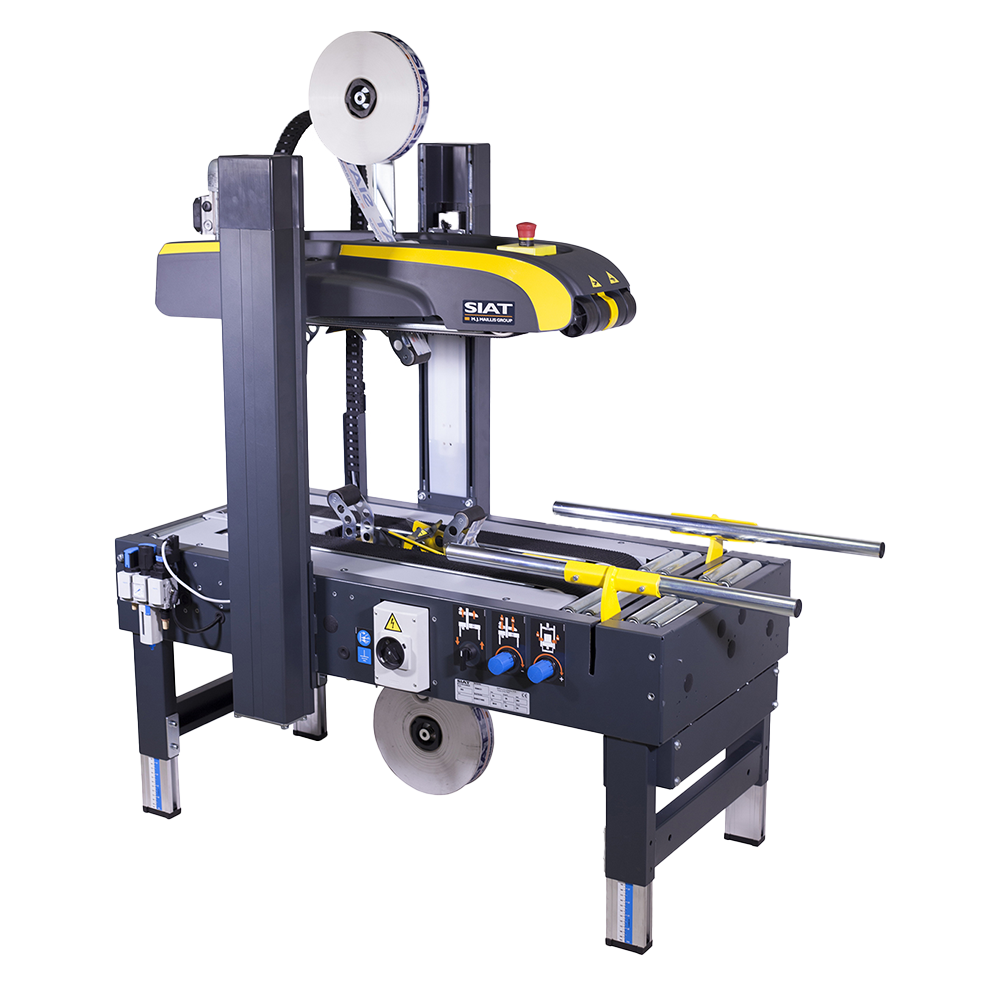

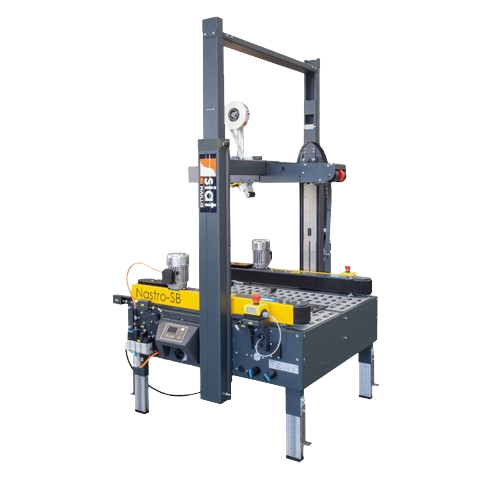

Tapping Machines

Wrapping Machines

Uncategorized

Adhesive Tape

Machinery

PET / P.P Strap

Shrinking Machines

Polyethylene Film

Materials

Case Erectors

Polyolefins

Strapping Machines

Agri Stretch Film

Strapping Tools

Net Pallet Wrap

Bundling Machines

Pallets

Boxes

Crates

Vacuum Machines